Participants will be provided with the essential knowledge and skills necessary for developing a material failure Root Cause Analysis (RCA) for material failure diagnosis

OBJECTIVE:

Failure analysis determines the root cause of failure should your equipment or asset fail or not perform as expected. The findings provide you with insights to resolve the problem – and take action to prevent recurrence.

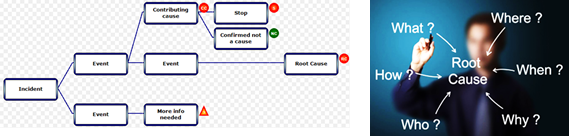

Root Cause Analysis (RCA) is the investigative process employed to determine the underlying event(s) responsible for failure(s). The underlying “root cause” event can be associated with the design, manufacturing, end usage conditions (e.g. human factors) as well as other elements of a system’s design.

TOPICS:

- Introduction to Root Cause Analysis (RCA)

- Data Collection

- Assessment

- What is Root Cause Analysis (RCA)

- How to Perform Root Cause Analysis (RCA)

- Introduction to Engineering Materials in Oil/Gas and process industries

- Introduction to materials failures

- Corrosion failure:

- Cost of corrosion

- Corrosion forms

- Corrosion mechanisms

- Corrosion control

- Mechanical failure

- Root Cause Analysis (RCA) technique

- Problem definition

- Failure investigation

Related Analytical Instrumentation & Techniques

- Optical Microscopy (OM)

- Scanning Electron Microscopy – Energy Dispersive Spectroscopy (SEM-EDS)

- Stereomicroscopy

- Fluorescence microscopy

- Focus Ion Beam (FIB)

- Raman spectroscopy.

- Comparison microscopy

Course Features

- Lectures 0

- Quizzes 0

- Duration 50 hours

- Skill level All levels

- Language English

- Students 1

- Assessments Yes

Curriculum is empty